Advanced Boundary Film Technology.

Steel Shield reacts chemically, under thermal conditions, with the contacting metal surfaces to form a complex surface attaching film of protection. Because Steel Shield’s characteristics are “electro-negative”, which causes it to seek out and affix itself to the metallic surface areas, the metal surfaces become uniform in charge and the result is a reduction in friction due to the Faraday reaction of repelling like-charges.

The process of Advanced Boundary Film formation is achieved through a unique combination of long-chain halogenated hydrocarbons and other proprietary additives that are highly stable and non-corrosive to the equipment’s metal parts, and pose no threat to the environment or waste oil recovery systems.

During this process, surface smoothing is accomplished, resulting in improved spread characteristics of the surfaces themselves. The final state of the opposing metal surfaces increases the fluid film strength, even more, resulting in greatly reduced wear while imparting extreme pressure (EP) properties to the opposing metal surfaces.

Steel Shield treats the Metal, not the Oil

The result is a virtual elimination of frictional wear and significant cooling of the entire lubricated area yielding higher energy savings and reduced metallic debris and acids in the oil. This is extensively proven through elemental oil analysis and Ferrography of the used oil, before and after the use of Steel Shield.

How Steel Shield’s Advanced Boundary Film Technology Works

Steel Shield reduces friction and wear

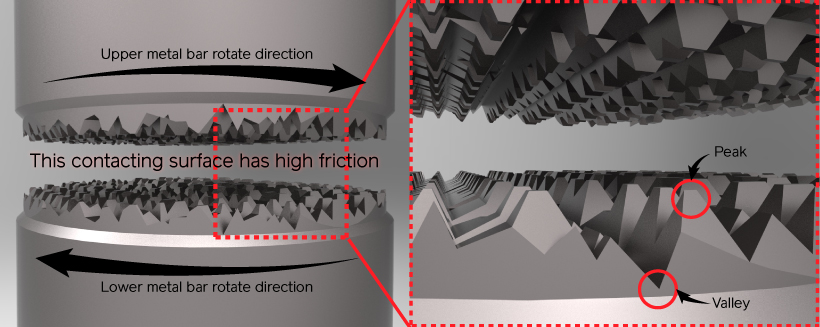

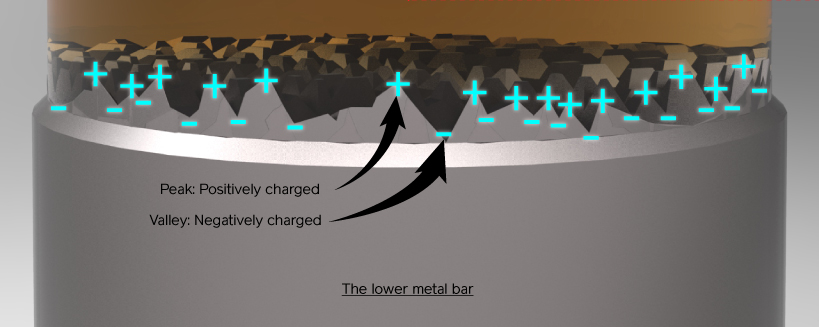

1. An Unlubricated Metal Surface

- Metal surface is characterized by a series of peaks and valleys

- Peaks (known as “asperities”) are positively charged

- Valleys (referred to as “micro-pores” and “fissures”) are negatively charged

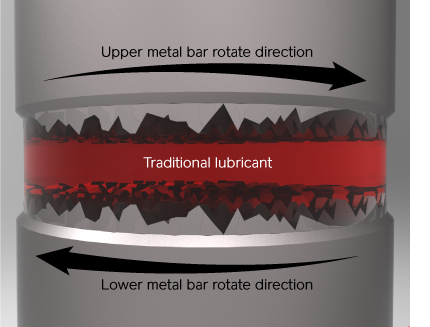

2. A Metal Surface with Traditional Lubricants

- Most lubricants help to slow the process of heat & friction to some degree

- When two metal surfaces contact each other & move in opposite directions, friction is caused, producing heat & metal deterioration

- Constant friction & electro-magnetic interaction causes the weakened metal to break off creating metallic debris & particles in the lubricant

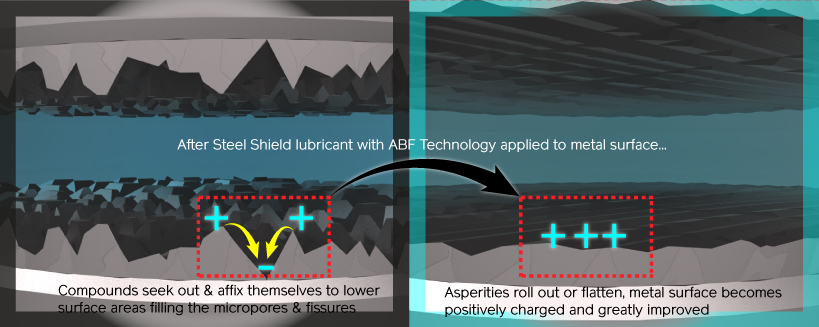

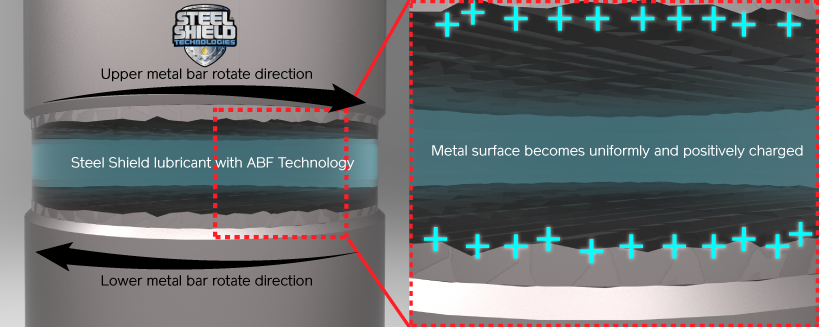

3. A Metal Surface With Steel Shield’s Advanced Boundary Film

- Forms electro-negative surface attaching compounds to seek out & affix themselves to lower surface areas filling the micro-pores & fissures

- Asperities roll out or flatten creating greatly improved metal surfaces

- Created in this process is a total positive state of polarity

- When metal surfaces become uniform in charge, there is a reduction in friction due to the Faraday reaction of like-charges

Close Up on the Metal Surface

Wearing of a Bearing Cylinder with Traditional Lubricant

Wearing of a Bearing Cylinder with STEEL SHIELD Lubricant

Steel Shield loosens and discharges dirt & debris

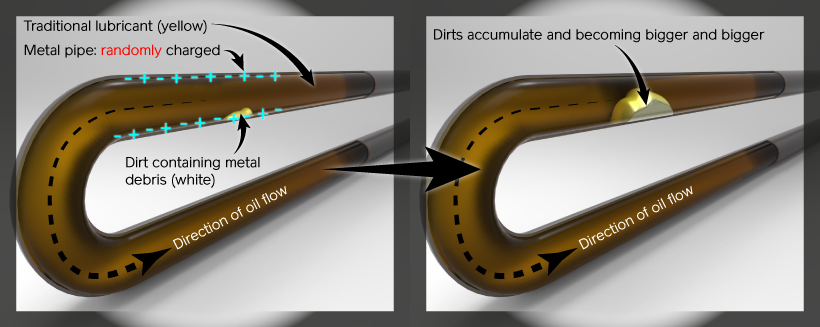

1. A Compressor System with Traditional Lubricant

Dirt and Debris greatly reduce the efficiency of the system.

- Both metal pipes and dirt are randomly charged

- Traditional lubricants cannot stop the formation of dirt and debris

- Thus, dirt always becomes bigger and bigger inside metal pipes which greatly reduces the efficiency of the compressor system

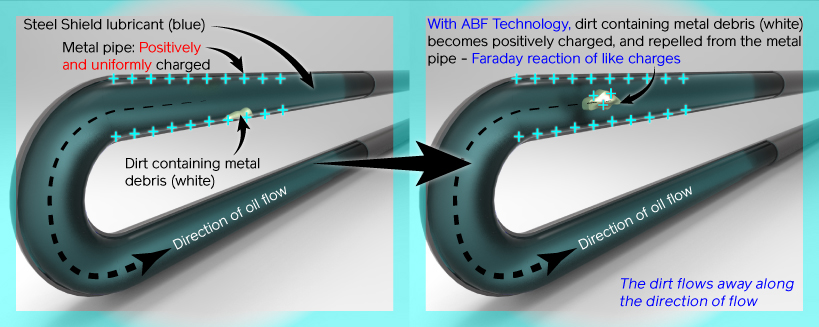

2. A Compressor System with Steel Shield Lubricant

Dirt is REPELLED due to Faraday’s law and detach from the pipe surface.

- Both metal pipe and dirt (oil with metal debris) are positively and uniformly charged by Steel Shield lubricant with Advanced Boundary Film Technology

- Dirt is repelled and detaches from the metal pipe surface due to the Faraday reaction of Like-Charge

- Dirt flows away along the direction of lubricant flow

- Thus, the efficiency of the compressor system greatly enhanced

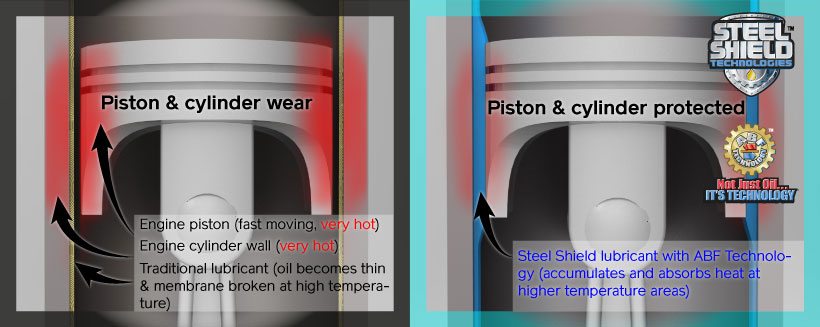

Steel Shield increases Dynamic Heat Transfer

Protecting Metals From High Temperatures

Engines run hot with Traditional Lubricant

Engines stay cool with Steel Shield

- Excellent resistance of the oil film at High Temperatures

- Superior thermo-oxidative stability